A permanent magnet DC generator is a type of wind power generator that uses a permanent magnet rotor to generate direct current electricity.

Table Of Content

According to our prior wind turbine lesson, an electrical generator is a revolving mechanism that transforms mechanical energy from the rotor blades (the prime mover) into electrical energy or power. Using Faraday’s equations of electromagnetic induction, the generator’s rotation induces a dynamic e.m.f. (electro-motive force) into the coils. Electrical generators come in a wide variety of shapes and sizes, but one kind that works well in a wind energy system is the permanent magnet DC generator, or PMDC generator.

There is no fundamental difference in the construction of permanent magnet DC machines employed as conventional motors or DC wind turbine generators. One PMDC machine may be used as either a motor to move a mechanical load or a simple generator to produce an output voltage, depending on how it is controlled. For this reason, the permanent magnet DC generator (PMDC generator) is the best option for use in a basic wind turbine.

We invite you to read: “Jamaican Hotel Runs a Hybrid Trigeneration System: Solar & Wind”

Connecting a DC machine to a DC source causes the armature to revolve at a constant speed proportional to the supply voltage and the magnetic field strength, transforming the machine into a “motor” that can generate torque. But if we use the rotor blades to spin the armature faster than the motor speed, we can turn this DC motor into a DC generator with an emf output that is proportional to the speed of rotation and the strength of the magnetic field.

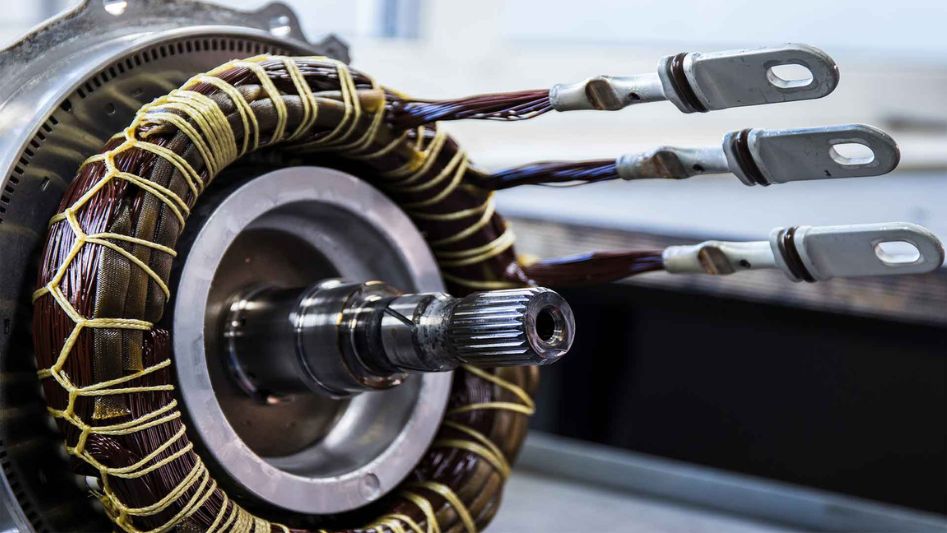

Common DC machines have the field winding on the stator and the armature winding on the rotor. Thus, they generate the necessary magnetic flux by means of a rotating output coil in conjunction with a fixed magnetic field. Carbon brushes are used to get direct current from the armature, and either permanent magnets or an electromagnet control this current by making a magnetic field.

An electrical current is created in the armature coils when they rotate through the static magnetic field. When the armature of a permanent magnet DC generator is in motion, the current flowing through it must go from the commutator or slip rings and carbon brushes to the generator’s output terminals.

Typical DC Generator Construction

DC Generator Construction

Different configurations of magnetic field coils and their connections to the armature allow for different designs of basic DC generators. A shunt-wound DC generator, where the primary field winding is linked in parallel with the armature, is one of the two fundamental connections for a self-excited DC machine. Series-wound DC generators have the field winding carrying the current linked in series with the armature. There are benefits and drawbacks to using any DC generator design.

Because the field (excitation) current in a shunt-wound DC generator is proportional to the output voltage, the magnetic field produced by such a generator grows in proportion to the rise in rotational speed. In addition, as the armature rotates faster, the voltage and electrical torque applied to it rise. Operating at a constant speed under changing loads, the shunt-wound generator’s voltage output is significantly more consistent than that of a series-wound generator. Due to power loss across the armature, the output voltage drops as the load current goes up.

If the load current is far larger than the design of the generator, the fall in output voltage becomes so severe that it causes massive internal armature losses and overheating. That’s why shunt-wound DC generators aren’t often used when massive continuous current demands must be met.

A DC generator with a series winding configuration has a field (excitation) current that is identical to the current delivered to the load. When the current drawn by the associated load is low, the excitation current is correspondingly low. This results in a low voltage and a weak magnetic field from the series field winding.

If the current drawn by the connected load is high, then the excitation current will be too. As a result, the series field winding produces a substantial magnetic field and a high output voltage. An important drawback of series-wound DC generators is their poor voltage control, which means they are seldom employed for variable loads.

Self-excited DC generators, whether shunt wound or series wound, have a significant drawback in that variations in load current result in significant changes in generator output voltage owing to armature response; as a consequence, these kinds of DC generators are seldom employed as wind turbine generators.

Short-shunt compound DC generators and long-shunt compound DC generators are both types of generators that use a “compound” connection to create DC current. The benefits of both types of DC machines may be combined into a single self-excited DC generator.

Allowing the field windings to be linked externally is another technique to get around the drawbacks of a self-excited DC generator. A separately excited DC generator is the result of this process.

We invite you to read: “New Wind Power Tech Added 1,050 MW for New Mexico”

Separately Excited DC Generator

A DC generator with its field winding supplied by an external DC source is called a separately excited generator. This means that the armature’s magnetic field flux can be kept constant by the excitation current under all load circumstances. Because there is no load on the generator, the voltage at the terminals is always the rated value.

Simply connecting a load across the output will cause current to flow and the generator to start supplying electricity to the load.

One of the numerous places an independently excited DC generator finds usage is in wind turbine generators. One drawback of DC generators is that a dedicated direct current power source is required to excite the shunt field in a wind turbine installation. Permanent magnets may be used to replace the field winding in a DC generator, eliminating the drawback and resulting in a PMDC (Permanent Magnet DC) generator.

DC Permanent Magnet Generator

Another way to think about the permanent magnet DC generator is as a DC brushed motor with a steady magnetic flux that is energized independently. Almost any brushed permanent magnet direct current (PMDC) motor can be converted into a generator, but they aren’t ideal for usage in wind turbines since the rotating field serves as a brake when used to produce DC current, reducing the rotor’s rotational speed.

Instead of using wrapped coils and a commutator linked by brushes to a wound armature, these DC machines use a stator with rare-earth permanent magnets like Neodymium or Samarium Cobalt to generate a very powerful stator field flux.

High-voltage, low-rpm DC machines are preferable when utilized as DC generators, since permanent magnet DC (PMDC) motors need to be run at speeds far higher than their rated motor speed in order to generate voltages even close to their rated motor voltages.

Permanent magnet DC generators have a distinct advantage over other kinds of DC generators in that their powerful stator field remains constant, allowing them to swiftly react to fluctuations in wind speed.

magnet that doesn’t go away Because there are no field windings or field coil losses in a DC generator, they are often smaller and more efficient than wrapped stator machines of the same power rating.

The stator’s permanent magnet pole arrangement also makes it less vulnerable to dirt getting inside. The permanent magnets may cause internal damage if ferromagnetic dust and metallic swarf (sometimes termed “turnings” or “filings”) are let in.

The permanent magnet DC generator is an excellent option for small-scale wind turbine systems because of its dependability, low rotational speed capability, and high efficiency even in mild winds.

Many permanent magnet DC generators with outputs ranging from a few watts to many thousands of watts are available “off the shelf.” Three variables control the DC voltage produced by a permanent magnet DC machine:

the stator-generated magnetic field. The strength and kind of permanent magnets utilized, as well as the generator’s physical size, all play a role.

The wire count indicates how many loops or turns there are in the armature. This number is set by the dimensions of the generator and armature, as well as the diameter of the wire used for the connection. The greater the input current, the lower the output voltage. The same holds true for wires: the bigger their diameter or cross-sectional area, the greater the current.

The armature’s rotational speed is determined by the wind turbine’s rotor blades’ rotating speed. The output voltage of permanent magnet DC (PMDC) generators and motors is linearly related to the rotating frequency.

Permanent magnet DC generators, commonly known as “Dynamos,” are the most prevalent form of DC generators for wind turbines and small-scale wind turbine systems used to charge batteries. Since dynamos are huge, heavy, and often have extremely robust bearings, you can put pretty substantial rotor blades straight onto their pulley shaft, making them a popular option for beginners in the wind power industry.

Because of their focus on efficiency rather than maximum power, the dynamos used in older diesel trucks and buses are ideal for use in wind turbines because they can produce the necessary voltage and current at slower speeds. The dynamos in most buses and trucks can produce up to 500 watts at 24 volts, which is more than enough to charge batteries and provide lights for a modest low-voltage system.

Traction motors like those seen in golf carts, forklifts, and electric automobiles are another form of PMDC motor that may be employed in wind power DC generators. High-efficiency motors with a voltage range of 24 to 48 volts are the norm for these applications.

Because the carbon brushes used to extract the produced current wear out rapidly and create a lot of electrically conductive carbon dust within the machine, DC machines used as dynamos and generators need frequent maintenance. Thus, AC alternators are put to work sometimes.

Since low-voltage DC may also be created by car alternators, they are another popular alternative as a simple DC generator for use as a wind turbine generator, particularly among newbies and DIY enthusiasts. In order to provide DC voltage and current, most automobile alternators use AC-to-DC rectifiers. An alternator is an electrical generator that uses a rotating magnetic field to create alternating current (AC), whose output voltage is typically 12 volts with three phases. The benefit of automotive alternators is that they are designed to charge batteries of either 12 or 24 volts.

Although enclosed PMDC generators are favored in wind turbine generating systems, normal automobile alternators are often open and cooled by ambient air blown through the generator, making some sort of weather protection necessary. They come in a wide range of sizes and power ratings to fit everything from small cars to semi-trucks. However, even though they are cheap and easy to find, they are not as good as the permanent magnet DC generators, which are bigger and more powerful.

Car Alternator Schematic

Direct-drive wind turbines, in which the blades of the turbine are attached directly to the generator’s primary pulley shaft, are the key to reducing complexity while simultaneously increasing efficiency. Any modification to their speed, such as the addition of gears, belts, pulleys, or any other mechanical device, results in energy waste, higher expenses, and complexity.

A three-bladed rotor with a five- or seven-foot (1.5- or 2-meter) diameter may attain speeds in excess of 1,000 rpm, but this is still too sluggish to be a suitable fit for most conventional automobile alternators, which revolve at rates of between 2,000 and 10,000 rpm since they are coupled to the car’s engine. Alternators can have their output and speed of rotation increased with the help of a pulley or a gearbox.

In addition, before an automobile alternator’s cut-in speed is reached, the excitation and, by extension, the generation process must begin with a tiny biasing current supplied to the field coils (often through the dashboard indication light).

The linked battery bank might provide the external field current, but doing so could potentially deplete the batteries even while the turbine blades are still during times of zero or low wind. The rotor shafts used to install pulleys on current automobile alternators are sometimes about 5/8 inch (17 millimeters) in diameter, which isn’t quite large enough to withstand the loads imposed by the whirling blades.

Finding a good DC generator is a challenging aspect of developing a small-scale low-voltage wind turbine for power generation.

When used in “off-grid” stand-alone systems to charge batteries or power low-voltage lights and appliances, permanent magnet DC generators are low-speed generators that are reasonably dependable and efficient in mild winds. Typically, their power curves are linear, and their cut-in velocities are approximately 10 mph. Permanent magnetic DC generators of the past were bigger, heavier, and more durable, but they are now harder to come by.

When it comes to low-voltage DC generators for wind turbines, the automobile vehicle alternator is a popular option among many do-it-yourselfers. An alternator mounted on the side of a vehicle or an internal combustion engine are two examples that may create electricity, although they are inefficient and need high rpm rates. A voltage input from an external source is also needed to power the electromagnets that generate the alternator’s internal magnetic field in a vehicle.

An internal regulator circuit of a car’s alternator limits the current flowing through it, preventing the alternator from overcharging the batteries. However, it is extremely dangerous to connect an automotive alternator backwards to the battery bank or to run the alternator at high speeds without the battery connected. Doing either of these things will cause the output voltage to spike to dangerously high levels (much higher than 12 volts) and will damage the internal rectifier.

The low-voltage DC generated by the permanent magnet DC generator is great for charging batteries and other small devices, but if we want to power larger mains-connected appliances or have a system that is “grid-tied,” we need to use an inverter to change the DC into an AC supply at 120 or 240 volts.

The synchronous generator is a new form of electrical equipment that will be examined in the upcoming Wind Energy course. In contrast to a permanent magnet DC generator, a synchronous generator may produce three-phase alternating current energy that can be fed into an existing power system.

We invite you to read: “China Building World’s Largest Offshore Wind Farm”

Conclusion

Due to their simplicity and efficiency, permanent magnet DC generators have gained a lot of traction in the wind power industry. In order to produce the magnetic field necessary for energy production, these generators use permanent magnets, negating the need for a separate excitation mechanism. As a result, these generators are more dependable and less time-consuming to maintain than others. Because of their versatility and adaptability, permanent magnet DC generators may be used in many different types of wind turbines. In conclusion, permanent magnet DC generators are a dependable and effective method of converting wind energy into usable forms.

FAQs

Can a DC machine be used as a wind generator?

DC machines with permanent magnets that are used as regular motors or as DC generators in wind turbines are built the same way.

Are permanent magnets used in wind turbines?

Extremely powerful permanent magnets are used in wind turbines and generators. Rare earth magnets, such as neodymium magnets, are used in some of the world’s largest wind turbines. These magnets are the strongest permanent magnets on the market because they include neodymium, iron, and boron.

Why is a permanent magnet synchronous generator used in a wind turbine?

Simulation, optimization, a permanent magnet, and a synchronous generator The Permanent Magnet Synchronous Generator (PMSG) has the most benefits over other types of generators used in wind turbines since it is reliable and secure during normal operation and does not need a separate DC supply for the excitation circuit (winding).

You May Also Like

- Wind Power To Cut Cargo Ship Emissions 20%

- What is the Next Generation Wind Technology?

- Discover The World Largest Wind Farm

- DIY: Wind Energy Set Up and Maintenance

- The Biggest Wind Projects Running Now