Wind Turbine Improvement

Human beings had a long history to use wind energy. Some examples are windmills and yachts. The subject to the research of wind energy is Fluid Dynamic, which is the study of how fluid (e.g. air, gas, water, etc.) flows and the force related in the flowing system. Fluid Dynamic is one of the oldest engineering subjects in the world.

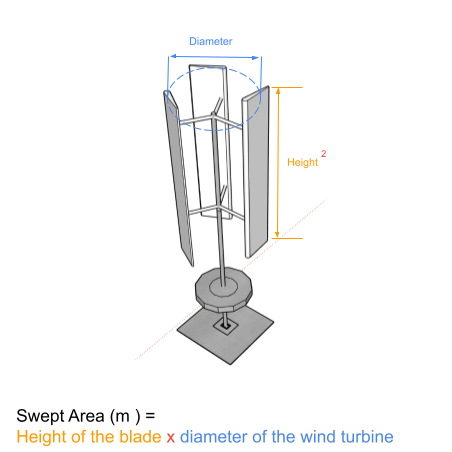

For Vertical Axis Wind Turbine, how we calculate the wind power is based on this formula:

Power = 0.5 x Swept Area x Air Density x Velocity3 x Coefficient of Power

In an objective environment, according to this equation, everything is fixed except the Coefficient of Power, which is what every researcher is working with. The bigger the Coefficient of Power, the more wind energy can be transferred to electrical energy.

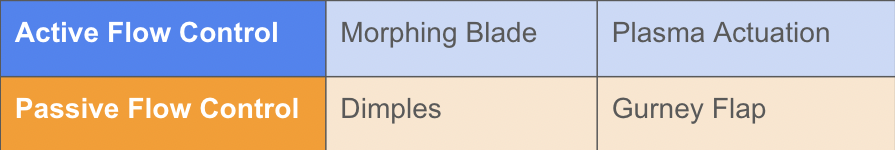

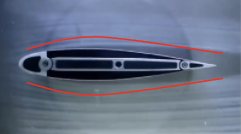

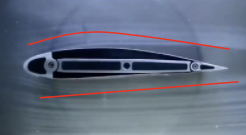

All the researchers are working with the blade shape for improving the Coefficient of Power. Basically, there are two types of design: Active Flow Control and Passive Flow Control. Active Flow Control refers to some sort of energy input that is necessary for active flow control to manipulate the flow, while passive flow control methods manipulate the flow by not requiring any exterior energy resources. Regardless of what types are used, the ultimate target is to manage the wind speed, the lift force, the drag force, and the turbulence generated around the blade.

Morphing Blade

In this design, the shape the wind turbine blade can be controlled and transformed by the mechanism inside the blade in order to harvest the maximum wind energy.

This is a very effective approach in which 20% improvement of coefficient of power is achievable.

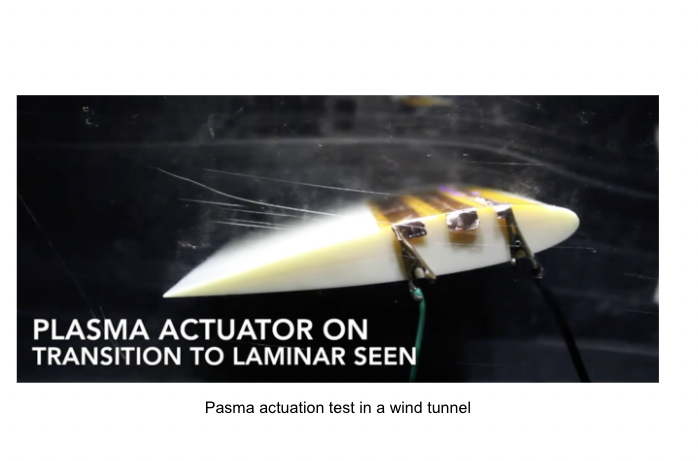

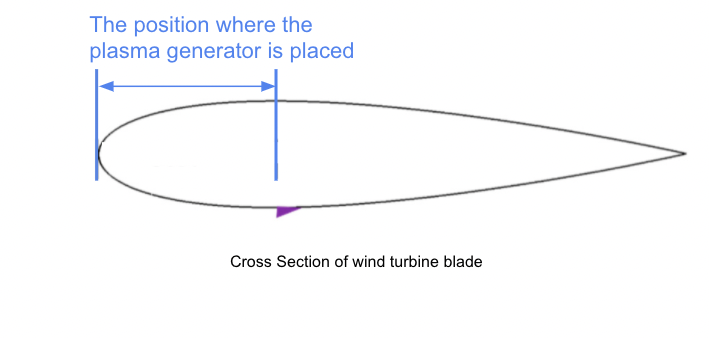

Plasma Actuation

The idea is to install a plasma-generating device on the wind turbine blade, and through the plasma to achieve boundary layer control. It can effectively enhance the power of the wind turbine and reduce noise.

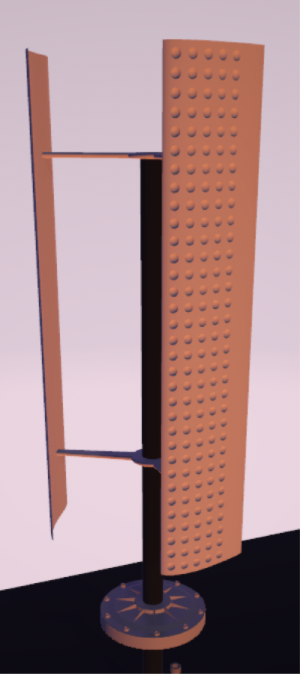

Dimples

It is interesting that the idea to apply dimples on the blade is origin from a golf ball. Do you know why there are so many dimples on a golf ball? Around 100 years ago, golf players discovered that used golf balls can be projected further than a new one. Then people started to study and found that there are many dimples made by the golf club. They discovered that the dimples can alter the lift force and drag force that make the ball go further.

Now scientists apply the same concept to the wind turbine blade. The size, depth, shape, and position of the dimples are factors to alter the performance. Although the research is complex and time-consuming, the production cost of the end product is low and high cost-effective.

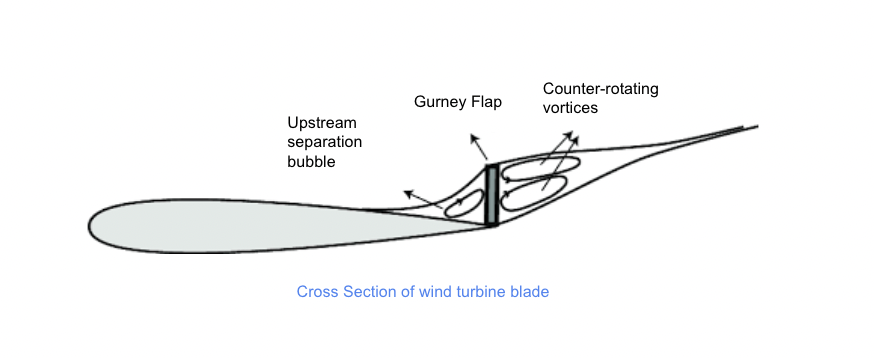

Gurney Flap

This is a very simple yet effective design and car manufacturers had used the Gurney Flap for their sports cars are spoilers for a long time. For wind turbine, a flap is applied at the trailing edge to enhance the wind harvesting.

Computation Fluid Dynamics

This is a kind of software for researchers to study and design the shape of the wind turbine blade. It simulates how air impacts the blade. The basic theory of it is quite simple, yet it is actually very complex research. The reason is that there are too many variables and each variable has a potentially big influence on the result. Take dimples as an example. Suppose there are 100 dimples on the blade. If we change the size, the shape, or the depth of 1 of the 100 dimples, it may lead to the total destruction of the blade. Therefore each blade is a result of a long time precise calculation and design.